Capsule Chemistry

The Future of Organic Synthesis

Automated chemical synthesis carries great promise of safety, efficiency and reproducibility for both research and industrial laboratories. As the field of chemistry automation grows, there is little doubt that it has already expanded the limits of what is practically possible.

However, the greatest challenge of automation for chemistry is finding the right balance between complexity and flexibility. In an ideal world, easy to use, low-cost automated systems would exist that could conduct a wide range of highly reproducible synthetic processes. Inevitably though, systems capable of carrying out a wide scope of chemistry need to have a great deal of functionality. Therefore, such systems are typically highly complex and very costly. As such, these technologies are neither accessible or suitable for all chemists.

A more realistic goal would be to have a selection of lower cost systems with reduced functionality for ease of use. Although such technologies are arguably less flexible, this issue is mitigated if the chemist has a whole toolbox of technologies available to them, from which they can select the most appropriate tool for the job. This flexibility to select from an easy to use, technology toolbox is particularly important for discovery chemistry, where the targets and synthetic processes can change rapidly.

Even with the most highly complex automated systems, the role of the human is still very important. Removing the human element completely is not desirable since the ability to notice the unusual or unexpected things happening in chemical reactions would also be removed, minimizing the potential for serendipitous discoveries.

Our goal is to provide automated solutions that enable the chemist to do their job in a more efficient, more productive and safer manner. With our technology, chemists work together with the system to automate the mundane or risky aspects of their work, freeing themselves up to do the things that only humans are good at!

Capsule Chemistry

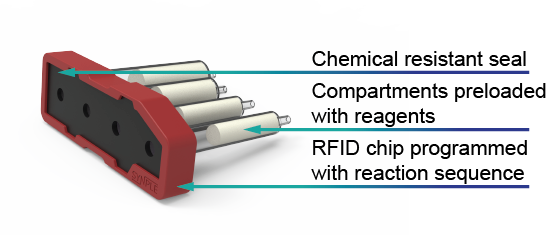

Our reagent cartridges consist of four different compartments, which are commercially available and come pre-filled with all the reagents needed for the reaction, plus the materials needed to isolate the product [link to available reaction classes]. Each cartridge also comes labelled with an RFID chip, which encodes the method need for a particular reaction.

To start a reaction, the cartridge is simply scanned on the machine and the appropriate method for that cartridge loads automatically. The standard method provided encompasses a broad scope [link to application notes] of starting materials. However, there is also the option to modify defined parameters within each method, e.g. reaction time, temperature, etc.

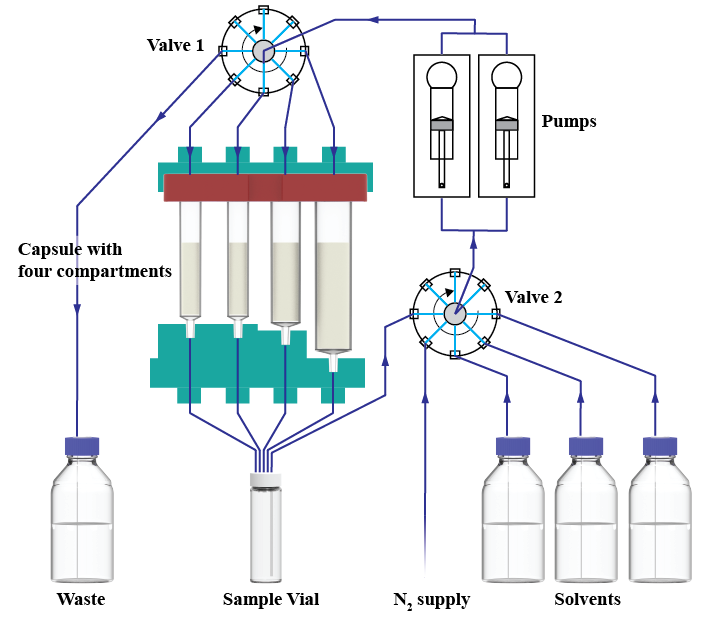

The main components of the instrument are two syringe pumps, two rotary valves and the cartridge-holder. During the process the individual reactions can take place in the cartridge itself or the reaction vial, which can serve as reactor.

Once the cartridge has been inserted into the machine and the starting material has been added to the reaction vial, the reaction can begin.

Following the initial preparation of the starting material, e.g. dissolution, the system circulates the starting material solution between the vial and the first compartment of the cartridge. After the defined period of time, the solution is then circulated through the second, third and/or fourth compartment, if necessary – depending on the type of reaction run.

Advantages of Capsule Chemistry

The use of pre-filled, commercially available cartridges offers multiple benefits:

Time-Saving

No time wasted searching for and weighing multiple reagents.

No need to optimise reaction conditions.

Quality Assured

Reagent quality guaranteed every time.

Cartridges supplied in sealed, dry foil bags.

Robustness and Reproducibility

Pre-optimized cartridges and methods reliably give the same results every time.

Safety

No handling or exposure to toxic reagents